As the future of the automotive industry heads toward the path of autonomous technology, the vehicles themselves aren't the only component with changes on the horizon.

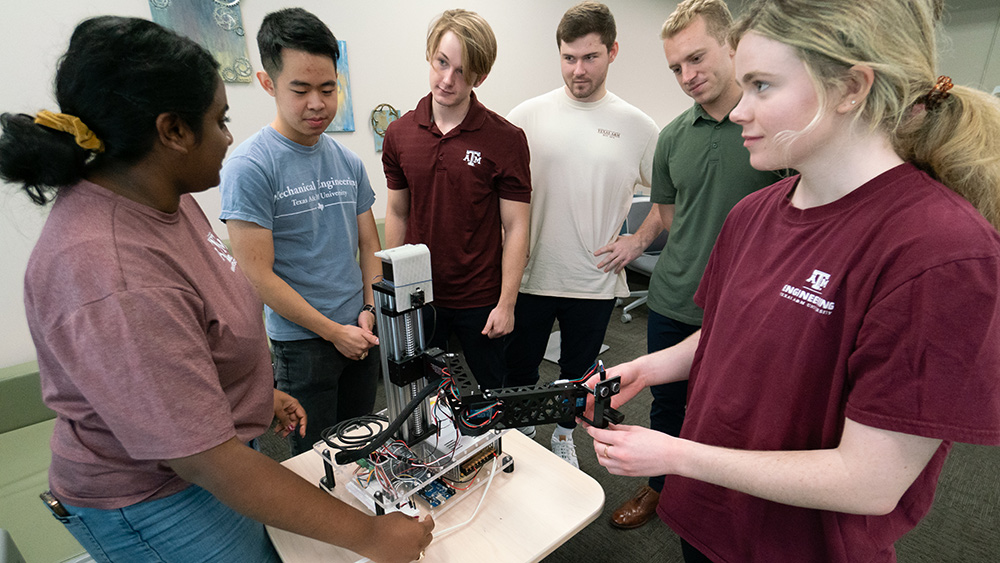

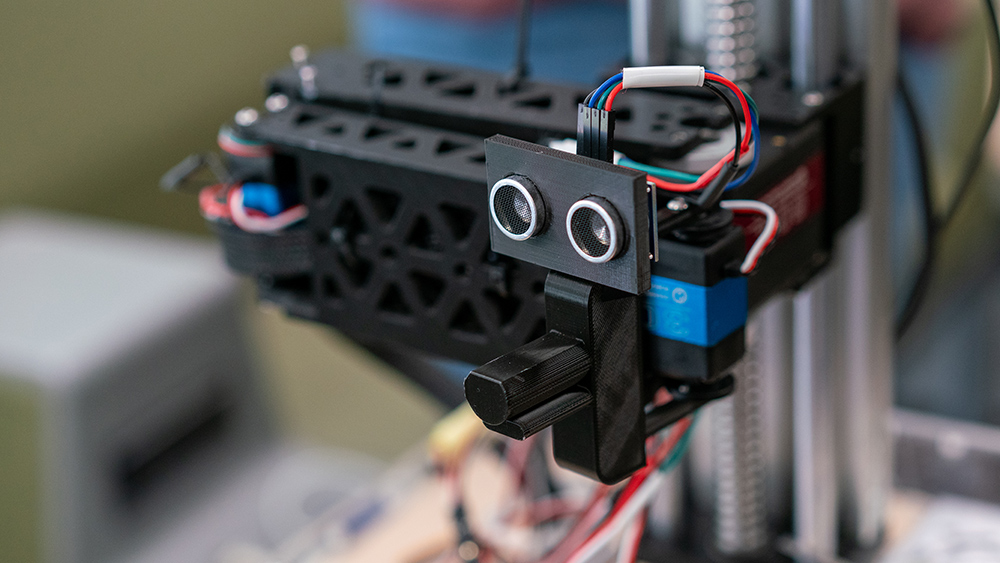

A recently graduated team of students in the J. Mike Walker '66 Department of Mechanical Engineering at Texas A&M University used their senior capstone design project to create a scaled-down mechatronic system capable of identifying a mock electric vehicle charging port and connecting itself.

Unlike many capstone projects, the Electric Vehicle Autonomous Assistant (EVAA) team did not have a traditional sponsor. Instead, the student-led project topic was proposed by team member Sharon Pearlnath and funded by the department as a Walker entrepreneurship project. It was guided by Dr. Joanna Tsenn, instructional assistant professor and senior capstone design projects coordinator, and Dr. James Hubbard Jr., Oscar S. Wyatt, Jr. '45 Chair I Professor.

In addition to Pearlnath, the EVAA team included mechanical engineering students Shaelyn Stacy, Eric Tseng, Aaron Hoyt, Ethan Russell, Skyler Roberts and Andrew Miskell. Their objective was to develop a mechanism that would locate the charging port of any electric vehicle autonomously — a valuable skill for autonomous vehicles of the future.

"As more vehicles can park themselves, the demand for an autonomous electric vehicle charging system will allow cars to park, charge and drive back to their owners without any further human interaction," said Stacy. "The focus of our design is to develop a system capable of connecting a charger to an electric vehicle autonomously."

The team's design won the Overall Showcase Capstone Award at the fall 2021 Texas A&M Engineering Project Showcase.

"The team was impressive from the start with their enthusiasm, motivation and ambitious plans," Tsenn said. "They worked hard and independently and learned many new skills to develop and prototype a system that integrates mechanical, electrical and software design. The team's win at the 2021 Fall Engineering Project Showcase was well deserved."

Pearlnath said she was astounded by the team's final product when reflecting on her original proposal. Although it was far from an easy project — thanks mainly to the complexity of the subsystems and various electrical, mechanical and software challenges — the team was well prepared by their education from the mechanical engineering department.

"As a freshman, I could have never imagined working on something so complex," Pearlnath said. "As mechanical engineering students, we were equipped to design and manufacture a working product to full conception."

As the team worked through challenges in integrating all the separate components needed for a successful final design, Tseng said it was a good lesson in the value of simplicity. At conception, the team initially planned to build a mobile, autonomous robot to complete the task at hand. However, given the time and financial limitations, they ultimately opted for a less complex design.

Tseng said he learned the value of starting with a simple approach and growing into increasing complexity when working to solve a problem.

"Even after drastically reducing the scope of the project, the project was still a huge challenge to implement, simply due to the implementation and integration of mechanical, electrical and software systems," he said. "Instead of starting out with an extremely complex problem, a better approach would be to start with a simpler solution and iterate and improve upon it over time."

The team is excited to see how major automotive companies implement their own versions of their project in the years to come.

"As things become more autonomous, electronic vehicle charging will follow," said Russell. "Companies such as Tesla and Volkswagen are already working on autonomous chargers to assist with the increasing need for public charging stations. We predict that in the next 20 years, cars and chargers will be fully autonomous and hope that other teams can pick up where we left off."