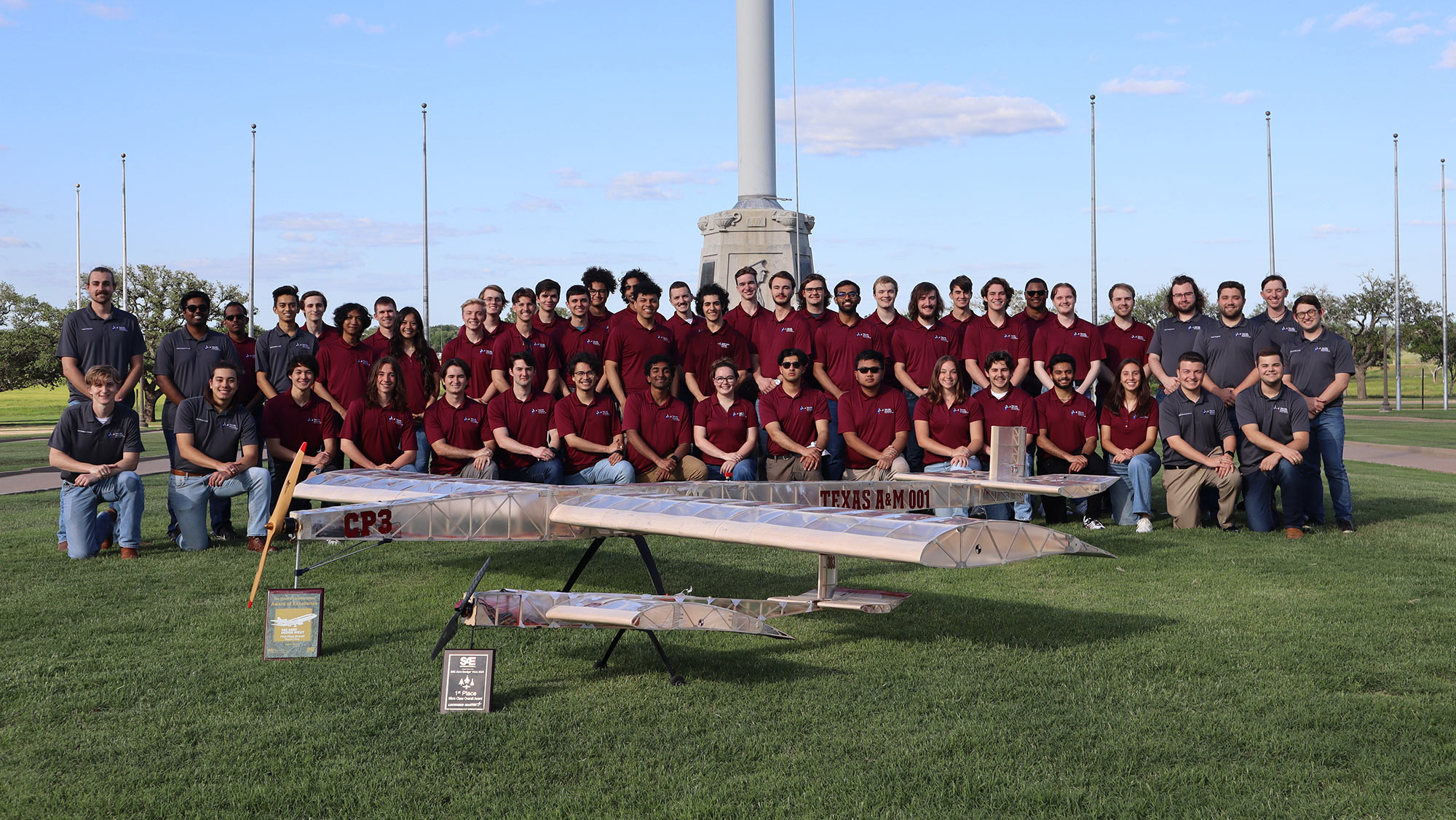

The Texas A&M University Society of Automotive Engineers (SAE) AERO Design team propelled their way to the top of the 2024 SAE Aero International Design Series West competition, capturing their record-breaking fifth consecutive Regular Class International Championship and being crowned Micro Class International Champions for the first time in history.

“I could not be prouder of what our students have accomplished, and it all started with a strong foundation many years ago,” said Scott McHarg, the advisor and pilot for the team. “Our success depends on what others have built and passed on.”

Competing against 76 universities from across the globe, the teams are responsible for creating aircraft that push the boundaries of design while meeting the criteria set out by the challenge. Once given the stipulations, the teams are given nine months to design and construct their aircraft, in addition to building a business model and presentation. The experience proposes real-world engineering scenarios to prepare students for industry, both with their creations and presentations.

“I think the success of this team helps members have confidence going into industry,” said Coby Arnold, the upcoming Micro Class Product Owner. “It’s the confidence that they know how to overcome challenges and work with people to achieve great things. While we are successful at competition, this team is ultimately about the students, and that’s what makes it great.”

It’s one thing to create an idea, but how will it be constructed, what are the implications of engineering decisions, and will the design be feasible? To answer these questions, the team must do more than they are asked and make decisions and sacrifices for the betterment of the team.

Since being formed in 2009, this is the first time the teams have swept the competition in both their classes. The team is composed of 60 students (30 for each team) from the Department of Aerospace Engineering, in addition to students from the J. Mike Walker ’66 Department of Mechanical Engineering.

“What is special about the program we have developed is the understanding that engineers must look beyond their computer-generated design and consider the practical aspect of engineering,” said McHarg. “It’s one thing to create an idea, but how will it be constructed, what are the implications of engineering decisions, and will the design be feasible? To answer these questions, the team must do more than they are asked and make decisions and sacrifices for the betterment of the team.”

Five in a row

The Regular Class competition focuses on engineering fundamentals for constrained takeoff under limited power available. The large airframe size requirements test students’ structural design optimization skills to achieve maximum payload weight performance during one complete circuit.

The aircraft designed by the team for competition has a wingspan of 15 feet and weighs 20 pounds when empty. According to regulations, the maximum payload weight that it can carry is around 35 pounds as no aircraft may exceed 55 pounds takeoff weight.

The differentiation between the team’s aircraft and others in the competition was mainly due to the team’s skills in optimizing the aircraft’s structural weight. According to Mason Viergutz, the 2023-2024 Aerodynamics, Systems, and Controls (ASC) apprentice product owner for the Regular Class, the aircraft had the largest wing in the competition.

“This enabled us to carry more payload than any other team,” said Viergutz. “Even in the rain at the competition, we were able to fly with a full payload. Watching our plane take off in the pouring rain at full payload broadcasted our team’s capability, showing that nothing will stop us from achieving our goals.”

Watching our plane take off in the pouring rain at full payload broadcasted our team’s capability, showing that nothing will stop us from achieving our goals.

According to Walker Buckle, the design lead for the Regular Class, the biggest struggle in creating the aircraft came from the combination of the scale of the aircraft with the minimal margin of safety. Because of the dictated ruleset, the team had to maximize the wing area within the bounds while creating as much lift as possible. This led to the aircraft constantly flying with minimal excess power, which caused it to struggle while taking off.

On the test flight before the competition, the team’s prototype failed. However, the team refused to quit, bonding together to bring home the win.

“Structurally, we chose to push the envelope, leading to a prototype and a competition aircraft failing in flight test,” said Buckle. “Previously, the building process would take us about a month for a single aircraft due to the size alone. Our only option was to keep our nose to the grindstone and finish building the aircraft we knew could win the competition.”

Solidifying the fifth win in a row speaks to the team’s rich history and sets the stage for future SAE Design team members.

“What winning this year meant was securing a legacy,” said Patrick Cramer, the Regular Class chief engineer, who has been on the team three of the five winning seasons. “With every flight test, we learned valuable lessons, even if it meant picking up wood scraps at the end of the day. Overall, winning the fifth year in a row sets a legacy; that legacy is carried on through the work we do teaching and implementing our culture and building up our engineers.”

First time for first place

For 2024, the stipulations of the Micro Class included developing a small, lightweight aircraft. With wildfire management in mind, the students were asked to consider large-volume fluid management concepts, meaning that the aircraft would be capable of carrying as much water-weight payload as possible.

The team’s aircraft was small, with a wingspan of roughly 3.6 feet. Despite this small span, it can carry up to six pounds of water, around a pound more than any other team competing. The design was successful due to its commitment to structural optimization, which allowed the team to design an aircraft that could carry more weight due to its low structural weight.

According to Kyle Bedrich, an ASC member of the Micro Class, the aircraft stood out as the largest aircraft in the competition. The aircraft was built with balsa and plywood, which led to the aircraft’s low empty weight. Additionally, the aircraft was covered in a clear wrap, further decreasing weight and exposing the internal structure.

The aircraft was designed to take off with a maximum weight of 10 pounds if the headwind was high enough. The headwind was not nearly as high as the team expected at the competition, but it still performed well because of the team’s takeoff performance analysis.

SAE AERO Design is so important to me because it has shaped me into the engineer I am today.

“The propulsion system maximized thrust and minimized electronics weight, contributing to the short takeoff performance and low empty weight,” said Bedrich. “All the team’s design decisions added to a successful design that can win in a large operating range.”

This triumph comes with learning over the past three years, building up the team’s design strategies, skillsets and accuracy.

“Passing down these methods is hugely important to us because a team will continue to be successful if knowledge is passed down in a way that new members will fully learn and understand,” said Bedrich. “Now that this philosophy has been created and applied to a winning design, we can consistently perform at a high level and create a successful legacy.”

This legacy is already starting with members who will return for the 2024-2025 season, such as Haru Tidmore, an ASC design lead for the Micro Class.

“SAE AERO Design is so important to me because it has shaped me into the engineer I am today,” said Tidmore. “The first person in SAE I talked to was Patrick Cramer, and I said to him, ‘I will bring the Micro Class team to the top.’ I can’t express how thankful I am to all the Micro class members, and I look forward to them continuing the newfound dynasty. I am proud to be an Aggie Engineer.”

Continuing the Legacy

The team has a rich history of success, including the four previous years as winners of the Regular Class and several other placements throughout the team’s history. However, this historic win sets a precedent for teams moving forward.

“Our goal was to continue along our path of excellence,” said Nathan Barton, the Micro Class Regular ASC apprentice. “We set our goals as winning each class. But more importantly, it is to build capable engineers who can take on challenges effectively.”

Moving forward, the students want future team members to understand the significance of being a part of Aero SAE. It is not only about winning but also preparing one another for success beyond Texas A&M.

“While we are extremely proud of our accomplishments, they symbolize how much effort we have put into our aircraft over the competition seasons,” said Justin Tolin, a Regular Class ASC member. “They show what we are capable of and are a steppingstone to explaining what makes us amazing engineers and sets us apart from the rest.”

Other team members from the SAE Aero team are as follows: Matthew Rossi, Chantz Elliott, Patrick Cramer, Mason Viergutz, Brandon Behenna, Konstantin Nelson, Walker Buckle, Marcus Facundo, Nicholas DeVault, Kishan Patel, Simran Kakkar, Timothy Kurtin, Harrison Harding, Hugo Emmanuel Trueba, Sadie Binz, Cooper Murphy, JD Kollar, River Spencer, Jose Guerrero, Samuel Crow, Tejas Vaidya, Om Waghela, Jackson Rahm, Caleb Thomas, Kristoffer Saeves, Laura Escamilla, Edward Eiche, Dylan Alexander, Malachi Drew, Luis Albos, Kaden Siebrasse, Elijah Todd, Hunter Hadden, Coburn Arnold, Haru Tidmore, Aadarsh Sudanagunta, Aarya Shah, Naren Sankar Sai Kolappan, Kyle Bedrich, Gautam Logeishwaran, Kenneth Hergenrader, Francisco Fernandez, Dylan Tysinger, Suhayl Guzman, Seth Johnson, Osvaldo Cortes, Gabriel Valencia, Isshaq Farah, Mauricio Trevino, Emma Hoaglin, Mason Coelho, Hunter Phillips, Lorenzo Martinez, Wayne Williams, Jaylon Palmer, Dhruval Rangrej, Joshua Stevenson, Kathryn Carter, Kara Grassau, Kevin Valencia, and Kyle Anderson.