Step into the Boys & Girls Club of the Brazos Valley in Bryan, Texas and you’ll find several carefully curated STEM exhibits. A local chartered member of The Boys & Girls Club of America, the Boys & Girls Club of the Brazos Valley provides programming to children of all backgrounds. The most recent addition to this programming, a pendulum design exhibit, comes courtesy of mechanical engineering seniors from the J. Mike Walker ’66 Department of Mechanical Engineering at Texas A&M University.

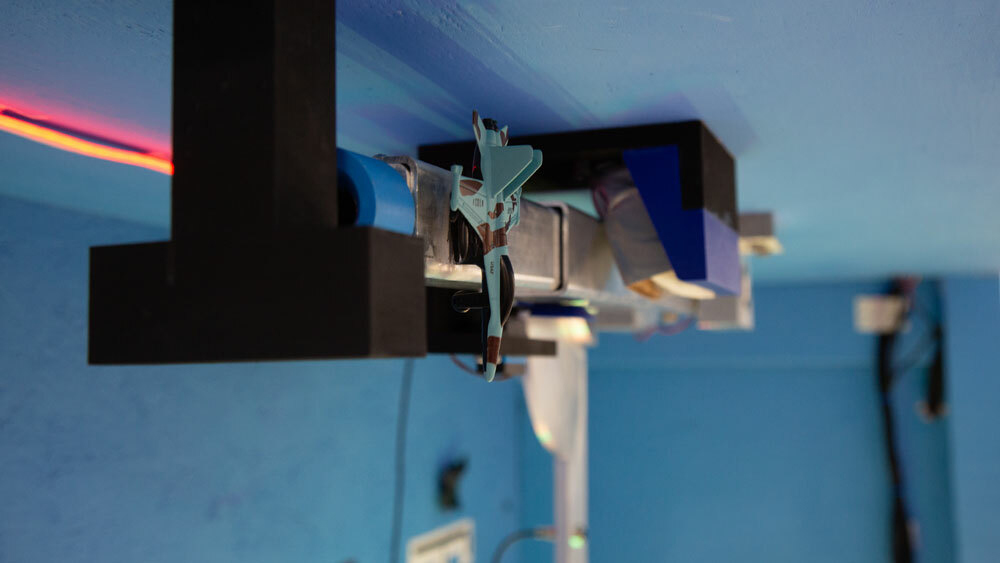

“Fly-By Drop-on-Specified Target” is the latest MEEN capstone team to bring mechanical engineering to the classroom in a fun and interactive way. The senior capstone design program is part of the curriculum for undergraduate seniors and prepares students to bridge the gap between classroom and industry. Their exhibit is a game where the objective is to release a ball from a swinging pendulum to hit a specified target.

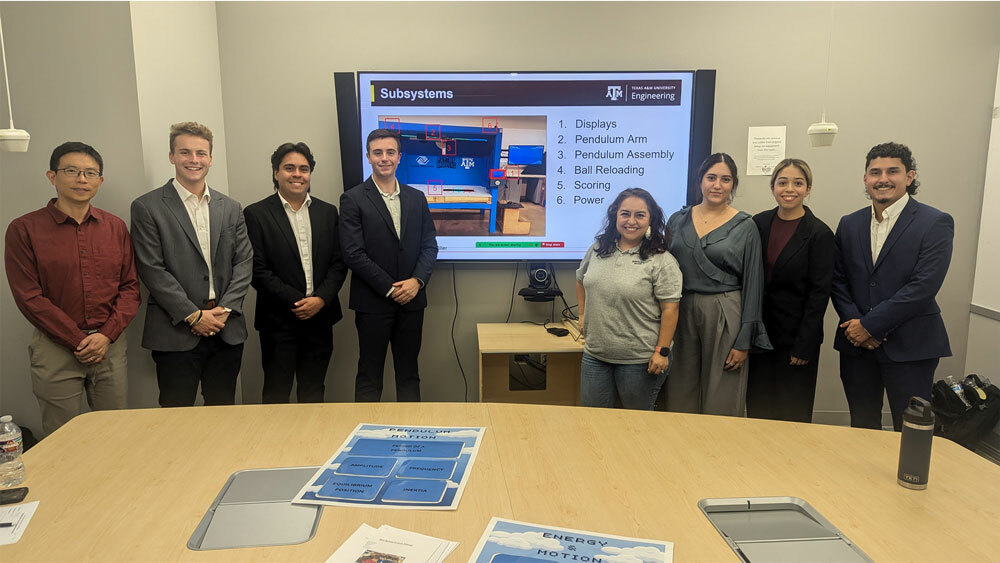

The team is comprised of Angelica Canchola, Benjamin Gutierrez, Sam Kelly, Joselyn Mendez, Logan Miller and Ronaldo Resendiz.

What problem is this project seeking to solve?

Ronaldo Resendiz: “There’s a need for more engaging and interactive ways to introduce fundamental STEM concepts to youth at the Boys & Girls Club of the Brazos Valley. Students are already accustomed to traditional teaching methods, so our objective was to create an experience that captures students’ interest and enhances their understanding of topics like projectile motion, in a hands-on, practical way."

What did the team create out of this project?

Logan Miller: “Our team created an educational STEM exhibit to teach the concepts of pendulums and kinetic motion in an interactive and entertaining way. The exhibit is a game where the objective is to release a ball from a swinging pendulum to hit a specified target. Our team used knowledge of mechanical engineering concepts to create an exhibit that is easy to use, safe and reliable.”

What was the most impactful part of this experience?

Benjamin Gutierrez: “This process kind of gave me a full circle moment. Personally, I didn’t start off in mechanical engineering, I transferred in from electrical. What’s funny is all of my jobs include the electrical and automation areas of the project. If you would’ve told me I’d be doing half the things I’ve worked on I would’ve laughed and said, ‘no thank you.’ It’s cool being able to think back on what my interests and capabilities were a few years ago and seeing how far ahead I am. It makes me excited for whatever comes next.”

What interested you in this project?

Sam Kelly: “I was particularly drawn to the idea of creating a functional kinematics exhibit for STEM students. The concept of building something tangible that could be used by future learners to grasp key scientific concepts really captivated me. There are always compelling projects that might help a company gain insight into a certain field or offer real-world solutions, but the prospect of contributing to the education of the younger generation felt deeply rewarding.”

What has been the biggest challenge?

Benjamin Gutierrez: “It was getting used to and eventually growing to appreciate the consistency of being confused about something. Every solution we were able to come across mostly created even more questions that needed to be answered. This project touches over a lot of the concepts within mechanical engineering, but also areas that are completely outside of it. I’ve been lucky enough that my team trusts me to oversee the electrical and automation areas. It has kept me learning, adapting, and pivoting constantly.”

What has been the most surprising development?

Joselyn Mendez: “Going from concepts and models to working with our fully functioning parts. Although everyone on the team is separated into their own subsystems, when a team member makes progress or finally gets something to work, everyone gets so excited and is in awe of the new little part we can add to our exhibit.”

What were the most important lessons learned working on this project?

Angelica Canchola: “We learned that a team’s success depends a lot on their collaboration. Our team has been very successful in our ability to work together. To meet our deadlines, we have to trust each other, work well together and communicate. Keeping continuous progress updates and continuous communication has allowed us to remain on track and ensure everyone is working towards an effective goal.”

What are you most proud of with this project?

Angelica Canchola: “I am most proud of the growth and progress each member has made. We began this capstone with theoretical knowledge on the systems and small amounts of previous experience. Throughout these two semesters, we’ve become experts in multiple fields from electronics, to machining, 3D modeling, coding, project management, presentations, and many more.

How do you think the capstone program will prepare you for the future?

Ronaldo Resendiz: “The capstone program has been invaluable in preparing us for the future, as it has provided us firsthand experience with the engineering design process that is crucial in the industry. From brainstorming concepts to refining designs, we have learned how to navigate real-world challenges, ensuring that we’ll be ready for similar processes in our careers. This project also required immense time management and collaboration, as we balanced multiple tasks and worked together to bring our final physics exhibit to life. By managing deadlines, dividing responsibilities, and integrating various subsystems, we gained critical skills that will be essential in any professional engineering role. “