In collaboration with Los Alamos National Laboratory (LANL), a team of senior mechanical engineering students at Texas A&M University set out to explore a high-stakes heat transfer challenge with real-world applications.

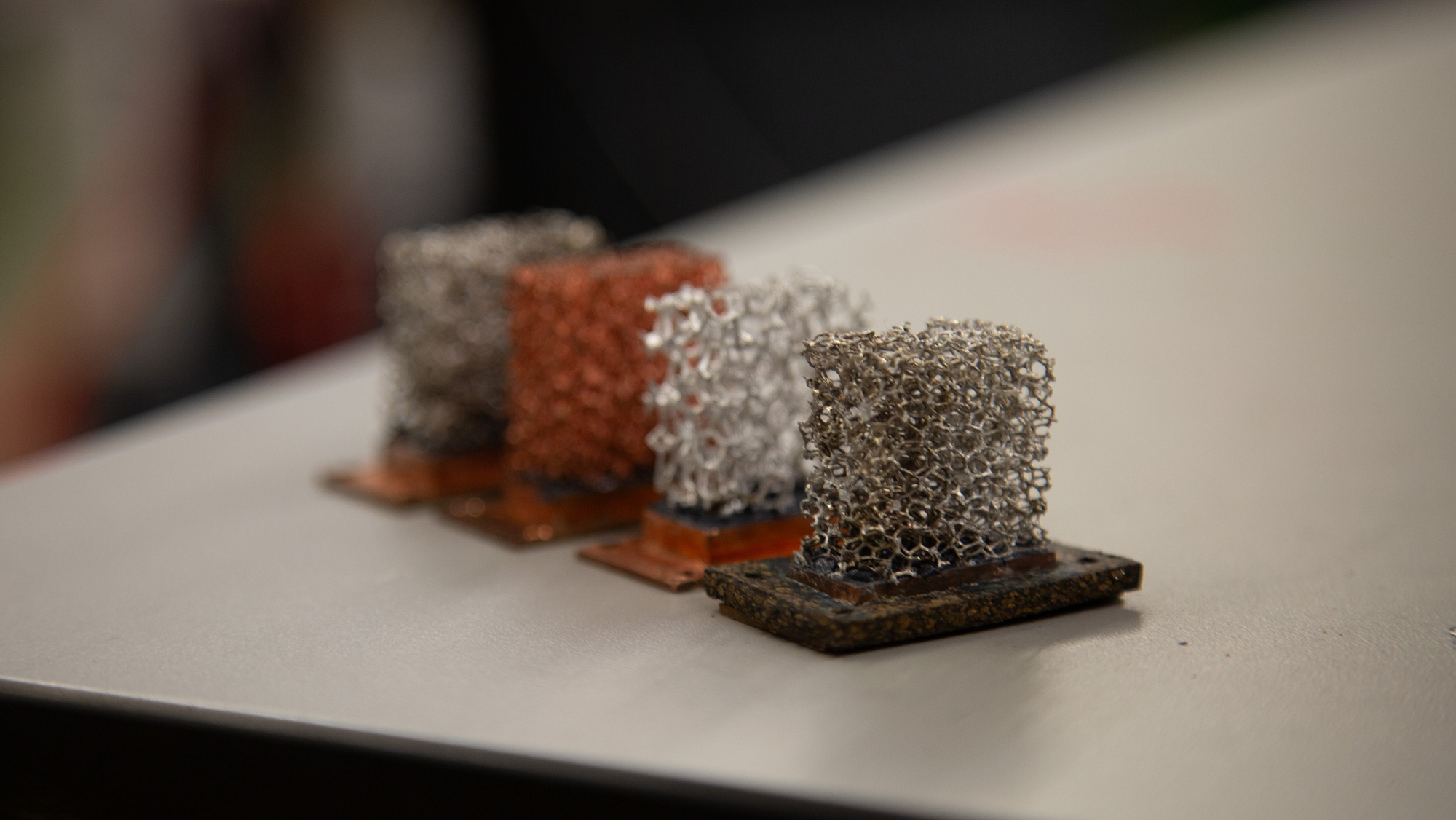

Aidan Ruiz, Mason Shuhart, Titus Klutz, John Kuhlmann, Liam Boone and Tanner Hawkins were tasked with evaluating the thermal performance of metal foams for use in LANL’s isotope production facility as part of their senior capstone design project. They designed and built a custom experimental setup to test foam samples under varying flow rates and heat loads to determine whether metal foams could offer improved cooling performance inside a particle accelerator.

Q: What did the team create out of this project?

A: To determine how effective metal foam is for this heat transfer application, we constructed an experiment to apply heat and water flow through the foam and measure the rate at which heat is transferred to the water and the pressure drop. This required us to supply enough water to match the Reynolds’ number of the actual isotope production application and facilitate the testing of four different porosities of metal foam. We also developed an Ansys Simulation that mimics our experiment to make our results more robust. Using this setup, we can determine which foam porosity would provide the most improvement if used in the isotope production facility. —Tanner Hawkins

Q: What was the most impactful part of this experience?

A: The most impactful part of this experience was seeing the Ansys Simulation and CAD Model come together in an experimental prototype. Being able to apply what we have learned in the past years from fluid mechanics, heat transfer, to coding and 3D modeling. And being able to combine these skills toward solving a real-world problem for LANL is incredibly rewarding. We divided responsibilities between us, which pushed us to trust each other and work together. That collaboration is what made this project special. — Titus Klutz

Q: What has been the biggest challenge?

A: One of the biggest challenges was building the scaled-down test apparatus to match the precision and constraints of our simulation model, and matching key components from LANL. Translating a theoretical design into a physical system introduces all kinds of hurdles, from using the right materials to ensuring watertight seals to integrating a high-wattage heating element. It is a hands-on lesson in how small fabrication details can have a huge impact on the quality of the data. — Titus Klutz

Q: What has been the most surprising development?

A: There have been many unexpected failures and successes throughout the project, but the most surprising development has been having one of our main components fail right before final testing begins. When reassembling our testing apparatus, we heard a snap, and there went our $500 ceramic heater. We ordered a replacement and used that waiting time to work on other aspects of the project and ensure we were better prepared to begin testing as soon as the part arrived. — Mason Shuhart

Q: What were the most important lessons learned working on this project?

A: The most important lesson we learned was task relegation. Our team is large with six members and a lot of work in CAD design, Computational Fluid Dynamics (CFD) modeling and manufacturing. The team split into two groups: the CFD team, who would work on the fluid dynamics model of the test section, and the manufacturing team, who would do the CAD design, weld the frame and machine parts. In the end, the team would come together and assemble and test together. This was crucial to do as we knew who was supposed to be doing what. — John Kuhlmann

Q: How do you think the capstone program will prepare you for the future?

A: The program is great practice for almost any job you are going to have. The ability to work effectively with a team on a project from start to finish is so important. From planning stages and budgeting to assembly and testing, whatever you end up doing in the field, you will have done it here. It also tests you on adapting to ideas that are different from your own. Diversity is a big part of what makes engineering better, and having a group with differing ideas on how the project should be done is the reason we can come up with effective products. Each member sees a different part of the solution that the others cannot and can catch mistakes that you would overlook in your work. — Liam Boone

With LANL as their sponsor, the students applied skills from across their undergraduate experience in fluid mechanics, heat transfer, 3D modeling, coding and simulation to deliver meaningful results for a national laboratory and gain valuable hands-on experience.

Sponsors like LANL are essential to the success of the Senior Capstone Design Program, providing students with real-world challenges that elevate their learning beyond the classroom. These partnerships offer critical technical guidance and funding and create opportunities for students to engage with industry-standard tools, timelines and expectations. This experience better prepares them for the demands of professional engineering careers.