Laboratory Overview

Operating Hours: 8am-4pm by appointment only

Location:

- Desktop polymer machines run in Thompson 105

- Laser cutting operates in Thompson 009

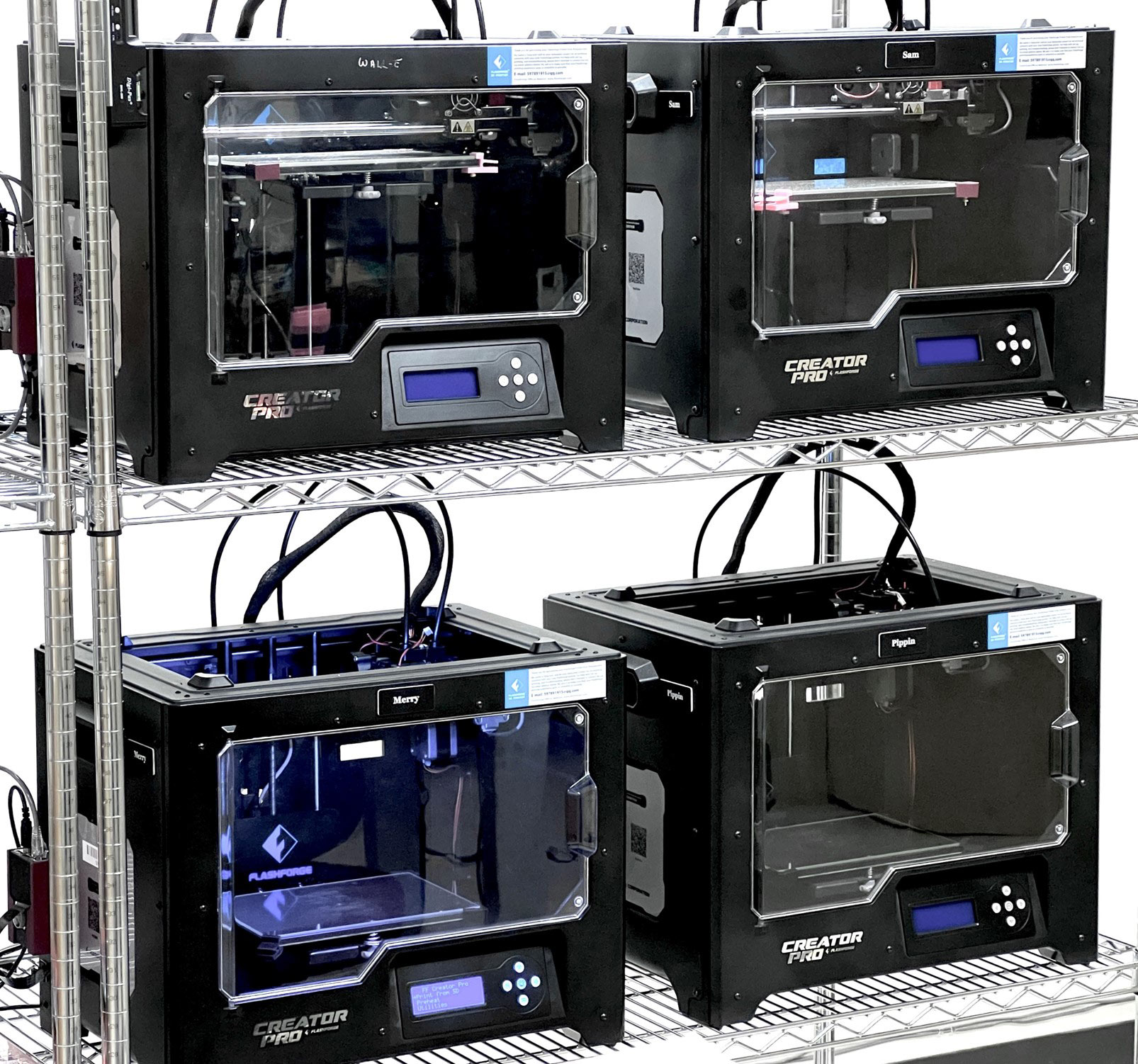

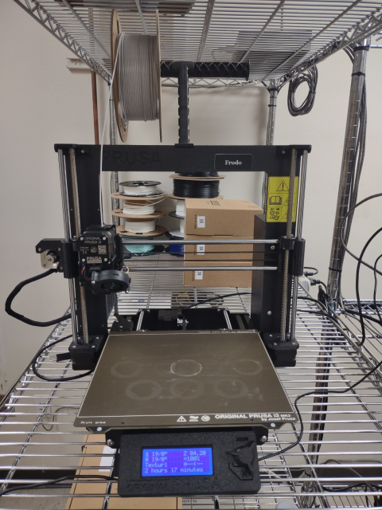

Polymer FDM

- Fused Deposition Modeling is the most popular method for 3D printing polymers at home and in industry. It is economical and achieves great mechanical performance. FDM printers extrude plastic through a heated nozzle, in many thin layers. More than 75% of our jobs use this selection, and turnaround time is fastest.

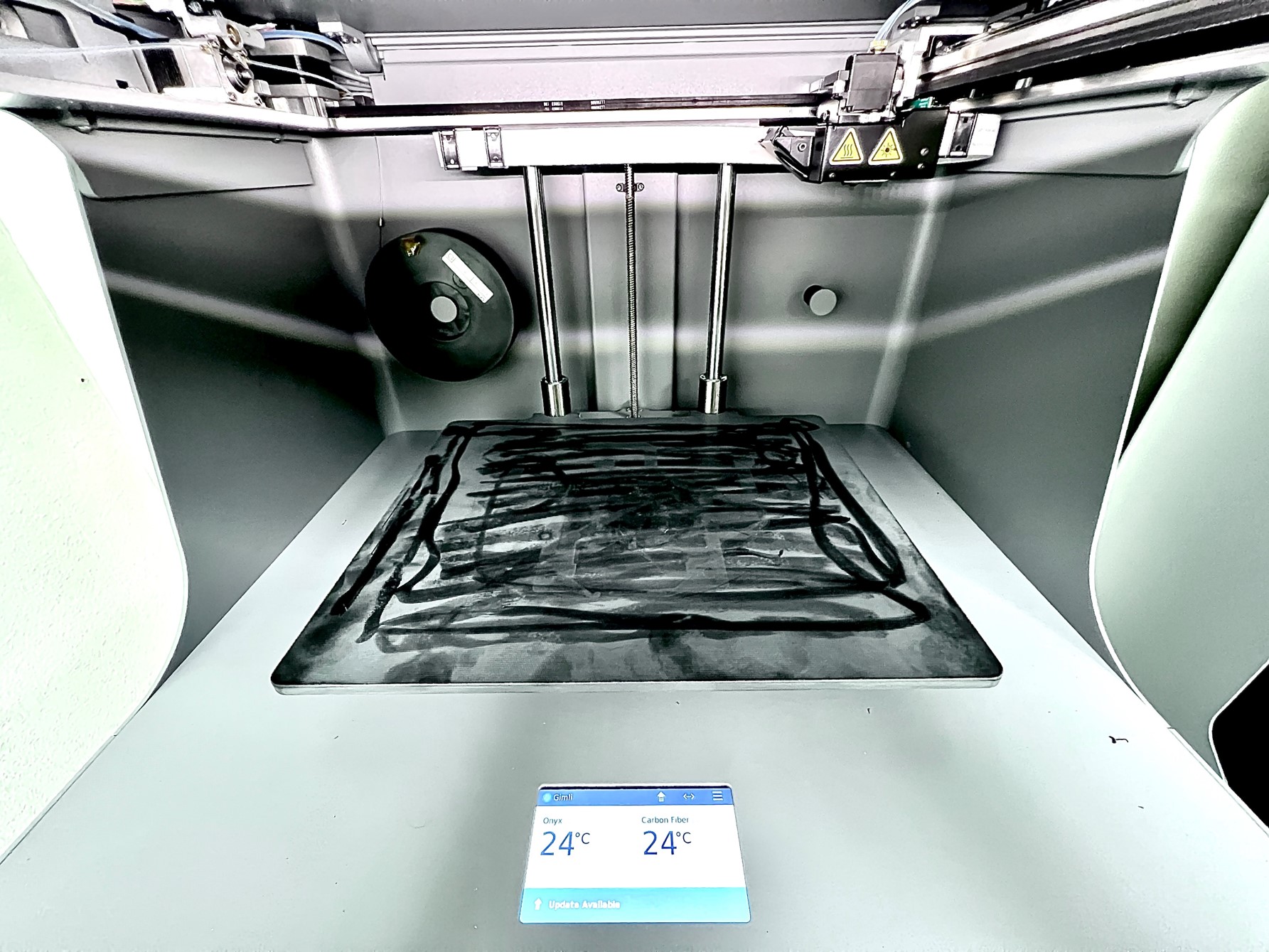

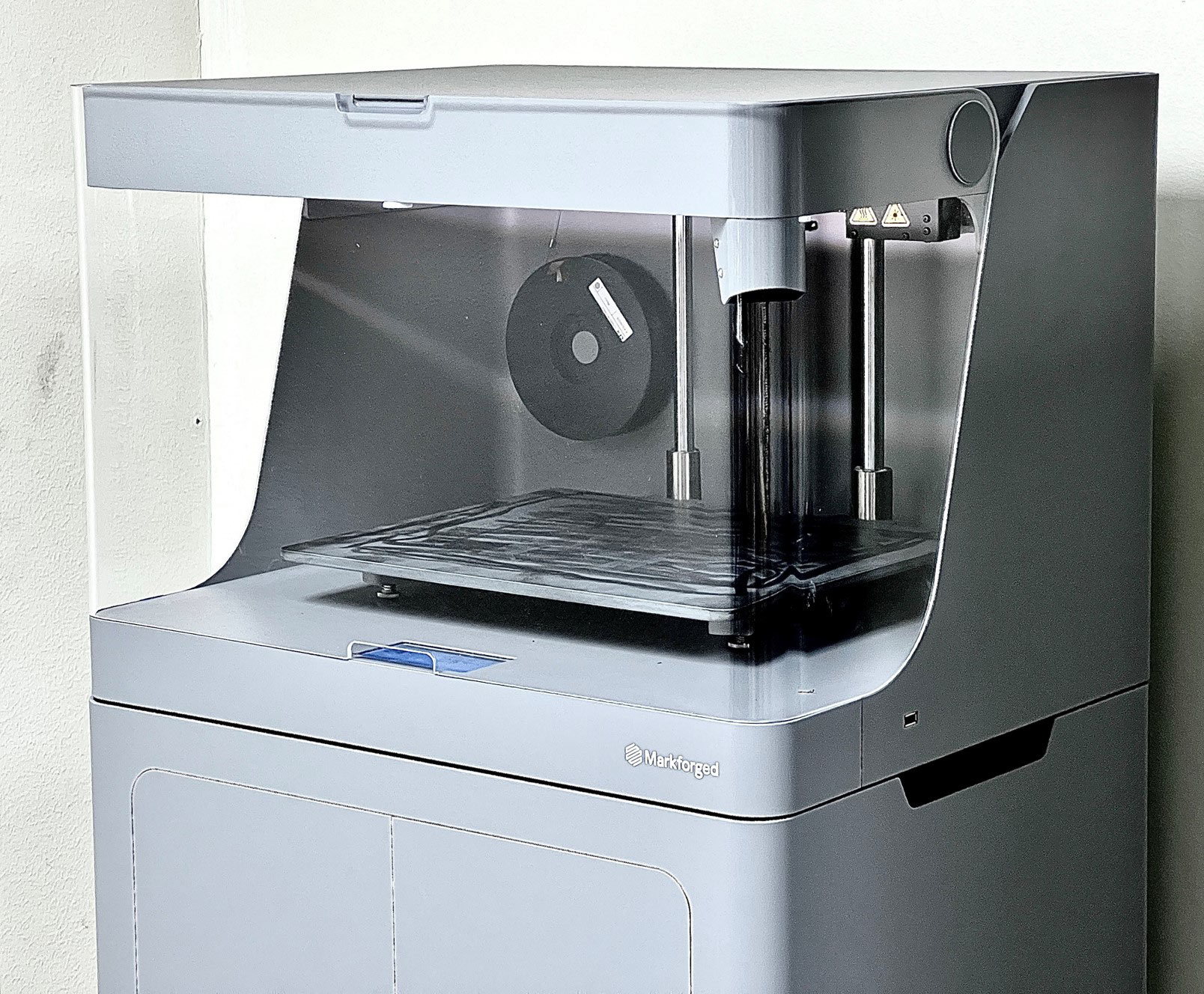

Polymer FDM with Carbon Fiber

- This technology takes FDM one step further by enhancing the mechanical strength and rigidity of parts which are intended for high loads. The cost may be 10x higher than comparable FDM builds without fiber reinforcement. Plastic parts with continuous fiber can often achieve performance that exceeds aluminum billet parts.

Laser Cutting

- Laser cutting is used in our lab for rapidly cutting parts from flat, thin acrylic. Typical thickness is 1/8 or ¼ inches, and we stock clear and black acrylic. This process is great for aesthetic finish such as control panels consisting of buttons and labels.

Water Jet

- New capability as of 2021, and still undergoing some testing. We are ready to cut some materials ranging below 1/4inch. Contact staff for inquiries.

Frequently Asked Questions

- Who can use the equipment?

- The machines are operated by the ETID staff team. When it is appropriate, the requesting student is trained on a process to execute their own builds.

- What are the fees?

- See Schedule of Fees

- What materials can be used?

- On desktop printing, PETG is the preferred plastic material, followed by PLA by request. ABS plastic is also compatible but may require longer lead time, and you may introduce your own filament (1.75mm diameter) by discussing it with our staff. For the industrial printers, ASA is used.

- What colors can be used?

- 5-10 common colors of PETG are normally stocked, and you may provide a spool of your own chosen color by talking with the staff.

- Can I supply my own filament?

- Yes – consult with staff to discover preferred manufacturers and limitations to material types. If your filament choice is outside of PETG and PLA, then it may incur some lead time to verify print settings.

Schedule of Fees

- Desktop FDM: No charge for ordinary undergrad projects.

- Uses Flashforge Creator Pro. There may be exceptions for intensive projects.

- Industrial FDM: Contact lab staff.

- Uses Stratasys model F270.

- Laser Cutting: Student must provide material.

- Additional fees for intensive projects.

- Water Jetting: Contact lab staff.

- Fiber-reinforced FDM: Contact lab staff.

Contact

Lab Management

- Water Jet Lab: Scott Butler

- Polymers Printing Shop: Christopher Smith

- Laser Cutting: Doug Burnett

- Metal Additive Manufacturing: Kyle Kuehl

- Labs Information Exchange: David Malawey (contact for documentation, web pages, and resource-sharing)