Take chances, experiment, and discover something new.

The National Science Foundation (NSF) funded – Multifunctional Materials REU provides an immersive summer research experience focused on the design, processing, characterization, and modeling of multifunctional materials. Students work closely with faculty mentors and graduate researchers, gaining hands-on exposure to experimental and computational approaches to address real-world materials challenges in energy, manufacturing, electronics, and sustainability.

Eligibility

This competitive undergraduate research program is open to students who:

- Are U.S. citizens or permanent residents

- Are enrolled at a four-year U.S. institution

- Are majoring in engineering or a STEM-related discipline

- Have completed at least one introductory materials-related course (or equivalent)

- Have completed at least two years of undergraduate study prior to the program

- Have a minimum cumulative GPA of 3.0

- Demonstrate a strong interest in research and a willingness to actively participate in ongoing projects

Application

The following documents are required for your application to be reviewed:

- A completed online application

- upload your statement of purpose and unofficial transcript with Fall grades in the application.

- State project/s and professor/s of interest in your statement of purpose.

- Two online recommendation forms

- Share this link with your references who are recommending you; they must fill out the form.

Program Dates

- Duration: 10 weeks

- Dates: May 26 – July 31, 2026

- Application Opens: Dec 14, 2025

Application reviews begin on Feb 16, 2026, and decision notifications are on a rolling basis.

Have questions? Contact bilal.mansoor@tamu.edu

Program Benefits

Participants receive a fully supported research experience, including:

- $7,000 stipend for the 10-week program

- On-campus housing and travel support (students are responsible for their food expenses).

- Supervision by a College of Engineering faculty member and a postdoctoral fellow or advanced graduate student.

- Exposure to state-of-the-art research laboratories and instrumentation

- Industrial site visits highlighting materials science applications beyond academia

- Professional development seminars (research communication, graduate school, careers) and social events.

- Participation in a campus-wide poster symposium with over 150 REU students

-

By the end of the program, students will:

- Gain hands-on experience in materials synthesis, processing, characterization, and computational modeling

- Learn how to design experiments, analyze data, and interpret structure–property–processing relationships

- Apply classroom knowledge to real-world engineering problems

- Strengthen technical communication, time management, and teamwork skills

- Build a strong foundation for graduate school and careers in industry, national laboratories, and academia

- Experience the culture and expectations of graduate studies

Program Projects

REU participants work on faculty-mentored research projects spanning multifunctional materials for energy, electronics, manufacturing, and sustainability. Projects integrate experimentation, modeling, and data-driven methods to support advanced materials research training.

-

Mentor: Dr. Bilal Mansoor

Background:

Rare-earth permanent magnets based on Nd–Fe–B (NdFeB) are among the most critical materials technologies underpinning modern society. They are essential components in electric vehicles, wind turbines, consumer electronics, robotics, defense systems, and data centers. Despite their widespread use, the United States remains highly dependent on fragile global supply chains for rare-earth elements (REEs), particularly neodymium, praseodymium, dysprosium, and terbium. A defining feature of NdFeB magnets is that their performance is governed not only by bulk composition, but by grain-boundary (GB) structure and chemistry, which control coercivity, thermal stability, and degradation. Hydrogen exposure—whether during manufacturing, service, or recycling—preferentially accesses these GB regions and can cause cracking, loss of magnetic performance, and premature failure.

Research Plan:

This REU project will investigate grain-boundary engineering and hydrogen processing in NdFeB hard magnets by examining how surface condition controls hydrogen access to grain boundaries and subsequent magnetic degradation. Students will work with commercial sintered NdFeB magnets representative of those used in electric vehicles, wind turbines, and other critical technologies, providing direct exposure to industrially relevant materials and magnet processing concepts. Identical magnet coupons will be prepared with controlled surface states to systematically vary grain-boundary accessibility. Changes in magnetic properties will be quantified before and after hydrogen exposure using standard magnetometry, and microstructural damage will be assessed using optical microscopy and scanning electron microscopy to identify grain-boundary-mediated cracking. By correlating surface engineering, hydrogen exposure, microstructural evolution, and magnetic performance, students will develop a mechanistic understanding of how grain boundaries govern hard-magnet reliability, while gaining insight into the broader magnet manufacturing, degradation, and recycling workflow relevant to critical materials supply chains.

-

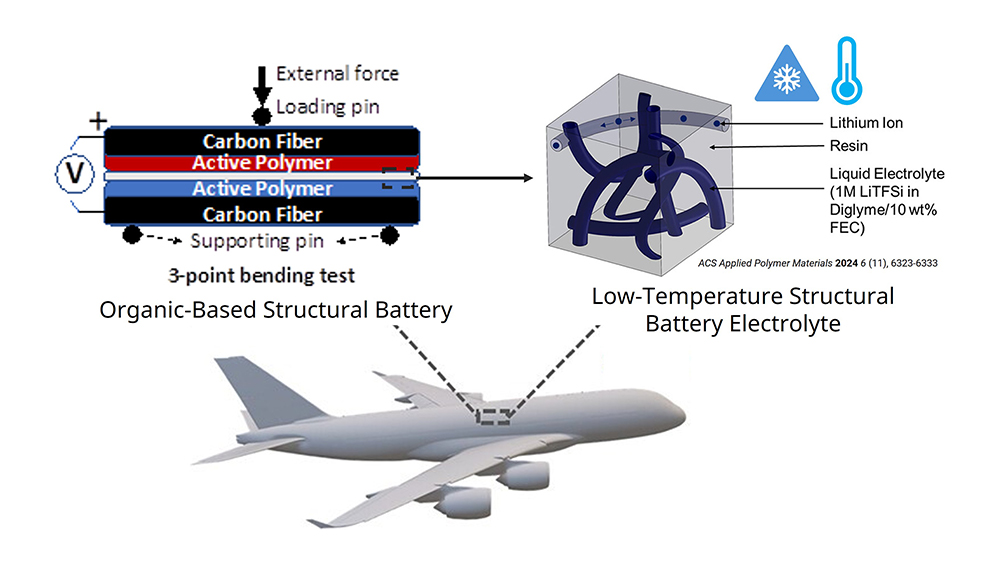

Mentor: Dr. D.C. Lagoudas, Dr. J. Lutkenhaus

Mentor: Dr. D.C. Lagoudas, Dr. J. LutkenhausBackground:

Structural energy and power systems offer both mechanical and electrochemical performance in a single multifunctional platform. These are of growing interest because they potentially offer a reduction in mass and/or volume for aircraft, satellites, and ground transportation. However, there is a natural tradeoff between mechanical and energy storage properties, making it difficult to synergistically optimize both. Common approaches center on modifying battery electrodes or electrolytes with stiff fillers such as carbon or glass fibers. This type of reinforcement leads to lower energy and power density. Here, we explore low temperature electrolytes combined with additive manufacturing to facilitate ion transfer. Our earlier work has shown excellent results for power density increase. This faster energy transport is crucial for space applications where the temperature is low, and diffusion is slow. low.

Research Plan:

The students’ summer activities will center on electrolyte fabrication, coin cell assembly, and mechanical and electrochemical characterization. The mentoring team will consist of a graduate student, and Lutkenhaus and Lagoudas. At the beginning of the summer, the student will fabricate electrolytes. Each of these fabrications is performed in the Lagoudas lab and tested in Aerospace Engineering lab on a regular basis. In early to mid-summer, the student will perform separate electrochemical (capacity, energy, power) and mechanical (three-point bending) characterization on these materials. The student will then perform in-situ energy density and power density characterization at different temperatures. In mid- to late-summer, the students will develop a multiphysics model to capture the experimental observation and explain the mechanism of the electrochemo-thermo-mechanical coupling on structural battery. The students will develop a test matrix to answer the following questions: How do temperature change the mechanical and electrochemical performances? How can we predict and improve the power and stiffness of structural battery for low-temperature applications?

-

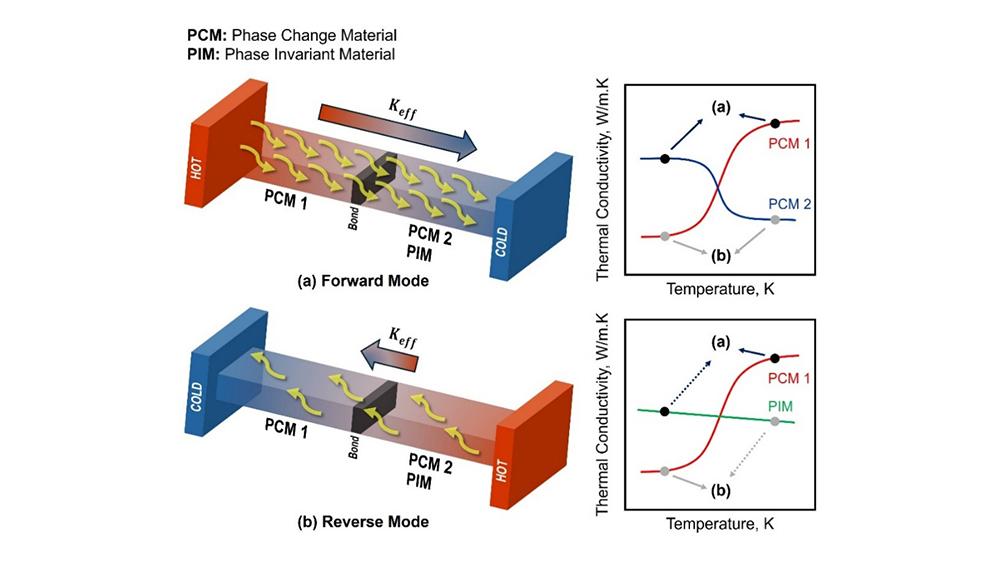

Thermal Diode Concept:

Figure: Schematic of a thermal diode concept using phase-change materials (PCM) and a phase-invariant material (PIM).

Mentor: Dr. Ibrahim Karaman

Background:

Solid-state thermal management has emerged as a critical challenge in modern energy systems, electronics, and thermal logic devices. Conventional materials typically exhibit smooth and monotonic variations in thermal conductivity with temperature, which limits their ability to actively regulate heat flow. In contrast, a growing class of multifunctional materials exhibits abrupt, reversible changes in thermal and electrical transport properties driven by solid-to-solid phase transformations. Among these, Ni-Mn- and Fe-Mn-based magnetic shape memory alloys (MSMAs) are particularly compelling due to their strong coupling between structural, magnetic, and electronic degrees of freedom.

In these alloys, reversible martensitic transformation (MT) can induce exceptionally large and abrupt transitions between low- and high-conductivity states, far exceeding the transport contrasts commonly observed in metallic systems. Recent work, primarily from the PI’s group, has revealed thermal transport switching ratios that are among the largest reported for solid-state phase transformations in metals and that remain robust under both thermally driven and near-isothermal, field-controlled conditions. This distinctive behavior establishes these alloys as unique phase-change materials (PCMs) for solid-state thermal switches, thermal diodes, and thermal regulators.

Research Plan:

In this project, we exploit the fact that the transport and magnetic responses of Ni-Mn- and Fe-Mn-based MSMAs are highly sensitive to composition, thermal history, and microstructure. By systematically controlling alloy synthesis routes and post-processing conditions, it becomes possible to tailor phase stability, magnetic order, and microstructural length scales, thereby engineering their thermal transport behavior. This approach provides a pathway toward adaptive, multifunctional materials that actively control heat flow without moving parts, directly supporting next-generation solid-state thermal management technologies. This project addresses how MT in MSMAs gives rise to exceptionally large and reversible changes in thermal transport, and how these changes depend on composition, microstructure, magnetic response, and thermal processing history. The central research questions focus on identifying the mechanisms that enable high-contrast thermal switching and understanding why different alloy families exhibit distinct transport behavior. The outcomes are directly relevant to real-world applications, including thermal switches, thermal diodes, and adaptive heat-flow control components for electronics and energy systems.

The REU scholar will engage in a structured, hands-on research program that mirrors graduate-level experimental materials research. The project begins with alloy synthesis using vacuum arc melting, followed by controlled heat treatments to modify phase stability and microstructure. The student will then measure temperature-dependent thermal and electrical transport properties to identify abrupt changes associated with phase transformations. Microstructural characterization will be used to directly link transport behavior to structural features across length scales. Throughout the project, the student will work closely with graduate mentors to interpret data and connect experimental observations to underlying physical mechanisms.

-

Mentor: Dr. Kaiwen Hsiao

Background:

Flexoelectric materials have a broad range of application ranging from sensing, actuation, and energy harvesting. Nevertheless, the flexoelectric effect is size dependent and is weak at the macroscale, as is evident from the small flexoelectric coefficients in the range of 10−5 to 10−3 C/m for ferroelectrics and ceramics and 10−10 to 10−8 C/m for polymers. The advances in high-resolution additive manufacturing has opened the route toward fabrication of architected, micron-scale polymeric materials. Despite the fast reaction speed and high structural fidelity in light-based additive manufacturing (AM), photo-crosslinked polymers are known to be plagued by weak mechanical characteristics. Heat-activated epoxy-containing cationic polymerizations or isocyanate and polyol reactions have been developed to form interpenetrating polymer network (IPN) structure during photopolymerization to achieve lower shrinkage and improve crosslinking inhomogeneity in 3D printed polymeric materials. Nonetheless, unique processing challenges exist when it comes to fabricating soft and elastomeric polymer lattice materials. Specifically, large molecular weight photoactive precursors are required to achieve the desirable deformability, that leads to increased resin viscosity and processing difficulties. This in turn limits direction fabrication of micron-resolution flexoelectric devices using high-resolution light-based AM.

Research Plan:

We will produce photo-active precursors containing thermally-activatable dynamic covalent bonds to form high molecular weight interpenetration network (IPN)7,8 that optimizes micro-patterning and elastomeric properties in light-based AM. By introducing dynamic covalent hindered urea bonds (HUBs),9 this approach enables our material to rearrange and form a secondary network from the photo-crosslinked structures that bypasses processing difficulties. We will tune our network modulus through introducing reactive diluents as molecular brushes. The material will be fabricated into 3D micro-lattices with our home-built high-resolution Continuous-Liquid-Interface Production (CLIP) printer. The capacitance response and flexoelectric response will be measured as the material is subjected to uniaxial deformation. Fabrication of micro-latticed based elastomeric material using CLIP will provide a route to exploit flexible, light weight capacitive sensor as flexible, light weight and self-powered wearable capacitive pressure sensors.

-

Mentors: Dr. Miladin Radovic

Background:

MXenes are a versatile class of multifunctional two-dimensional (2D) ceramic nanosheets with diverse compositions, and tailorability for different applications including energy storage, catalysis, electromagnetic interference shielding, sensors, composites, and batteries. They have general formula is Mn+1XnTz (n = 1-3), consisting of early transition metals (M), carbon/nitrogen (X), and surface terminal groups (Tz) such as -F, -Cl, -OH, or –O bonded to outer M layers. MXenes are typically produced by selectively etching an A group element (often Al) from Mn+1AXn (MAX) phases, using strong and often hazardous etchants like concentrated HF. However, large-scale production faces challenges due to synthesis difficulties and MXene's chemical instability. Recently, we have demonstrated that challenges in achieving a scalable synthesis of high-quality MXenes stem from the intricate process of selectively etching the A layer and the subsequent overarching of MX layers.

Research Plan:

Our core-shell model highlights the critical role of specific etching parameters, including the choice of etchants, their concentrations, etching temperature, particle sizes of the parent MAX phase, and the amount of etchant applied. These factors significantly influence the rates of A-layer etching and over-etching of MX layers, ultimately impacting the yield of MXenes. Furthermore, our recent findings have introduced safer alternatives to traditional etchants, such as (i) a mixture of organic quaternZary fluoride salts with milder acids and (ii) molten fluoride salts. These discoveries open up new possibilities for the scalable production of high-quality multifunctional MXenes using safer etching methods.

-

Mentor: Dr. P. Shamberger

Background:

Trends in electrification of vehicles, domestic heating and cooling, and the growth of data centers are straining the capacity of the electricity grid. Simultaneously, the growth in installed capacity of intermittent renewable sources (wind, solar), contributes to deep imbalances between power supply and demand. Distributed thermal energy storage (TES) can meet this demand by storing energy in the form of process heat (/cold) in a thermal reservoir at an order of magnitude lower cost than electrochemical battery energy storage. However, TES faces two primary challenges: 1) the lack of chemically stable materials which store heat reversibly at temperatures relevant for HVAC systems (5 to 20 °C), and 2) the cost and complexity of current thermal batteries, which is driven primarily by the complicated brazed metal heat exchangers required to achieve sufficiently high heat storage rates. Multifunctional shape-stable thermal energy storage materials can address both of these challenges.

Research Plan:

The core technology developed under this proposal consists of cross-linked polymeric networks supporting and providing shape stability to salt hydrates (termed ‘salogels’). In general, salogels represent a poorly understood hybrid material system that is situated at the interface between soft organic materials and hard inorganic phases. Consequentially, these materials are very sensitive to aspects of polymer chemistry (chain length, cross-linker chemistry, etc.), as well as the chemical potential of water in the system. Under the proposed effort, we will advance our understanding of salogels, particularly in the area of nucleation and growth of inorganic phases within physically or chemically cross-linked polymeric frameworks. These fundamental advances will be coupled with advancing our understanding of applied design of transient thermal energy storage modules and systems.

In this project, we will 2) develop the chemical formulations for stiff, shape-stable salt hydrates supported by low concentration polymeric networks and 2) will design low-cost thermal batteries based on slabs of these shape-stable salt hydrates with thin polymer encasings, which are in direct contact with heat transfer fluid. Students will be involved in i) material synthesis (varying chemistries and synthesis properties to attain desired rheological properties), ii) thermal slab production (encapsulation and polymerization process), and iii) measuring thermal response using a cold plate setup.

-

Mentor: Dr. Qing Tu

Background:

2D Hybrid Organic-Inorganic Perovskites (HOIPs) are burgeoning low-cost, high-performance semiconductor materials with great potential in a wide range of energy and electronic applications. These materials manifest unique mechanical behaviors different from those of their 3D counterparts and 2D inorganic semiconductors. In particular, despite being ionic bonded and having limited dislocation activity, 2D HOIPs show significant creep behavior at room temperature. This is critical to improve the mechanical reliability of devices based on these materials and realize the full potential of strain to tune the functional properties of 2D HOIPs. Furthermore, 2D HOIPs offer tremendous chemical space to engineer their functional properties. Establishing a structure-property relationship regarding their creep behavior is vital to guide the materials design of 2D HOIPs toward reliable and durable device applications.

Research Plan:

The students will work with the graduate student mentors and Dr. Tu to investigate the creep behaviors of prototypical 2D HOIP single crystals and their dependence on key structural parameters. The students are expected to 1) synthesize 2D HOIP single crystals using solution-based methods; 2) Assist graduate students to perform instrument and AFM nanoindentations; 3) Analyze the creep data from the experiments to shed light on the creep mechanism; 4) Investigate the creep behavior of 2D HOIPs under service environment, e.g., with electric field, temperature variation and/or radiation.

-

Mentor: Dr. Raymundo Arróyave

Background:

Phase diagrams govern which materials phases are stable as a function of composition and temperature, but generating them for emerging functional materials is often slow and expertise-intensive. In this REU project, undergraduate researchers will use PhaseForge, an open-source, AI-enabled platform, to predict phase diagrams for functional materials lacking established thermodynamic databases.

Students will generate thermodynamic data using machine-learned interatomic potentials, integrate these data into CALPHAD-based models, and compute equilibrium phase diagrams across composition–temperature space. The project emphasizes physical interpretation of phase stability and introduces uncertainty-aware predictions, allowing students to assess confidence in phase boundaries and explore how data limitations affect results.

Participants will gain hands-on experience in computational thermodynamics, scientific programming, and reproducible research while contributing to open-source workflows. This project provides a practical introduction to AI-assisted materials discovery and prepares students for graduate study or data-driven careers in materials science and engineering.

-

Mentor: Dr. Svetlana Sukhishvili

Background:

This project will investigate self-healing behavior in dynamic covalent polymer networks exposed to external stimuli (temperature, atomic oxygen, irradiation). Specifically, the focus will be on the networks formed via through furan-maleimide Diels-Alder (DA) bonds. DA polymer (DAP) networks are intrinsically healable due to the bond exchange reaction between furan and maleimide junctions at the fractured surfaces and have the potential to replace traditional thermosets. DAP-based materials have widely tunable chain rigidity (glass transition temperature, Tg, from -20 °C to 40 °C) and exhibit healing above their glass transition temperature.

Research Plan:

DAP networks are ideal self-healing materials due to the reversible nature of DA reaction. However, the self-healing kinetics of DA materials has not been explored. We hypothesize that the healing rate is related to the concentration, spatial distribution of the available unreacted furan sites, as well as to the proximity to network glass transition temperature.

This hypothesis will be tested in a series of systematically designed self-healing experiments. The results of this work are essential for future applications of these materials as shape-adaptable, re-processable materials with promising applications in consumer and defense sectors, as well as soft robotics.

The REU student will work with a graduate student to develop, construct and characterize novel dynamic covalent polymer networks using several epoxy monomers that were previously studied in our group,7-11 as well as other monomers which yield polymers with different chain rigidity12, 13.

The REU student will:

(a) construct 2-3 networks with strategically varied monomer compositions and network processing conditions (temperature, time, and solvent) (Task 1);

(b) study degree of DA conversion using FTIR, glass transition and network dissociation temperature using DSC (Task 2);

(c) explore kinetics of self-healing using DMA and establish its correlation with the network molecular structure and distribution of the unreacted furan sites (Task 3).

-

Mentor: Dr. Yuxuan "Cosmi" Lin

Background:

Modern semiconductor chips play a critical role in both daily life and scientific research, powering technologies ranging from smartphones and cloud computing to artificial intelligence. As the demand for faster computation and greater energy efficiency continues to grow, semiconductor chips are designed with ultra-high-density transistor integration to support increasingly complex tasks.

As transistors are packed more closely together, metal interconnects, which serve as the critical pathways for signal transmission and power delivery, must be scaled down correspondingly. However, interconnects have recently emerged as a major bottleneck in chip scaling. Conventional interconnects, typically composed of polycrystalline copper nanowires and Ta/TaN liners, exhibit a sharp increase in resistivity due to enhanced electron scattering at grain boundaries, surfaces, and metal-insulator interfaces when scaled below 40 nm.

These scattering mechanisms degrade both conductivity and long-term reliability, making it difficult to meet the electrical requirements for future chips. To address these challenges, this project will explore both interface engineering and advanced conductor materials to suppress grain-boundary and surface scattering.

Research Plan:

This project focuses on growing nanoscale metal films (such as Cu, Ru, and Mo) on monolayer 2D material substrates (such as MoS2 and graphene). The goal to obtain films with larger grain size, less grain-boundary density, better crystallinity, and better alignment between the 2D substrate and the metal with a narrow in-plane orientation angle distribution. These characteristics are expected to reduce electron scattering and the resistivity increase in downscaled interconnects.

In this project, the REU student will learn fundamental principles and receive hands-on training on material synthesis, electron microscope characterization, and other relevant material characterization methods. Through literature review, the students will study key concepts such as nanoscale interconnects and resistivity size effects. The student will explore different deposition parameters, such as film thickness, deposition rate and substrate temperature, to prepare a series of metal thin-film samples on the 2D material substrates.

Then they will characterize these samples with transmission electron microscopy (TEM) to study grain morphology, and selected-area electron diffraction (SAED) combined with fast Fourier transform (FFT) analysis to study the in-plane orientation angle and epitaxial relationship between the metal films and the 2D lattice. At the end of the project, they will also use I–V measurements to analyze the electrical properties.

Principal Investigators

Ibrahim Karaman

- Department Head, Materials Science & Engineering

- Professor, Materials Science & Engineering

- Regents Professor

- Chevron Professor I

- Office: RDMC 245

- Phone: 979-862-3923

- Email: ikaraman@tamu.edu

Bilal Mansoor

- Associate Professor, Materials Science & Engineering

- Office: RDMC 201B

- Phone: 979-458-6887

- Email: bilal.mansoor@tamu.edu

Investigators

Raymundo Arróyave

- Associate Department Head for Research, Materials Science & Engineering

- Professor, Materials Science & Engineering

- Chevron Professor II

- Presidential Impact Fellow

- Chancellor EDGES Fellow

- Engineering Dean’s Research Fellow

- Affiliated Faculty, Industrial & Systems Engineering and Mechanical Engineering

- Office: RDMC 226

- Phone: 979-845-5416

- Email: rarroyave@tamu.edu

Kaiwen Hsiao

- Assistant Professor, Materials Science and Engineering

- Office: RDMC 201A

- Phone: 979-458-8645

- Email: kwhsiao@tamu.edu

Dimitris Lagoudas

- Interim Department Head, Aerospace Engineering

- Professor, Materials Science & Engineering

- Robert C. “Bud” Hagner Chair of Engineering

- University Distinguished Professor

- Regents Professor

- Office: HRBB 517, RDMC 300F

- Phone: 979-458-1378

- Email: lagoudas@tamu.edu

Yuxuan "Cosmi" Lin

- Assistant Professor, Materials Science and Engineering

- Affiliated Faculty, Electrical & Computer Engineering

- Office: RDMC 214

- Phone: 979-458-6889

- Email: yxclin@tamu.edu

Miladin Radovic

- Associate Department Head

- Professor, Materials Science & Engineering

- Director, Materials Characterization Facility

- Office: RDMC 302F

- Phone: 979-845-5114

- Email: mradovic@tamu.edu

Patrick Shamberger

- Director of Undergraduate Programs, Materials Science & Engineering

- Associate Professor, Materials Science & Engineering

- AZZ Inc. Fellow

- Office: RDMC 227

- Phone: 979-458-1086

- Email: patrick.shamberger@tamu.edu

Svetlana A. Sukhishvili

- Professor, Materials Science & Engineering

- Director, Soft Matter Facility

- Office: RDMC 219

- Phone: 979-458-9840

- Email: svetlana@tamu.edu

Qing Tu

- Assistant Professor, Materials Science & Engineering

- Office: RDMC 210

- Phone: 979-458-9353

- Email: qing.tu@tamu.edu